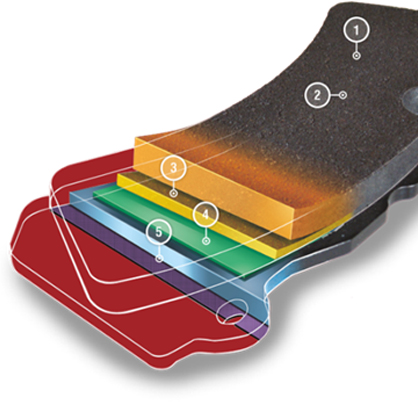

Brembo Brake Pad Materials, Treatments and Processes

1. OE Quality

More than 100 different compounds. This is the result of the ongoing research extensive testing in the laboratory as well as on the road.

2. Scorching

Surface heat treating to ensure maximum efficiency even at the highest temperatures. Uses the technical specifications required by the Original Equipment.

3. Substrate

Heat insulation between pad, piston and brake fluid to dampen noise and vibrations.

4. OE direct moulding

OE direct moulding Pressing Process. The high pressure values allow for adhesion of friction materials to the metal support with maximum precision.

5. Metal support with shim

Decreases noise while maintaining braking safety. The various layers of the shim (rubber – steel – rubber) ensure a further reduction of vibrations and noise.